Health standers

The Egyptian Minerals And Salts Company at Fayoum (EMISAL)

applies a set of health standards to ensure the safety of the final product.

1 – Purpose:

Staff hygiene and good health practices for workers.

2 – Responsibility:

- Safety and Health manager.

- Production and packing managers in all factories.

- Heads of the packing, quality, food safety departments in all factories.

3 – Instructions:

3-1 Personal hygiene

- Workers who deal or have contact with the products should keep their hands and exposed parts of their arms clean.

- Workers must wear clean uniform, while maintaining a high degree of personal hygiene, and fully adhering to good [proper] hygiene practices while working, to prevent contamination of food products.

- Workers who deal with food products must not wear jewelry and other personal belongings while working and adhere to the applicable health policy.

3-2 Health practices for workers:-

Every shift, the Occupational Safety and Health checks the employees ’application of good manufacturing practices (GMP) in relation to the health policy to packing the sodium chloride and vacuum salt manufacturers, which include the following:

- Use a head covering to cover all hair.

- Wearing clean uniform that cover all hair areas of the body while handling products and raw materials.

- Not to wear jewelry or watches.

- Not to use perfumes with a strong smell

- No personal belongings.

- Not to chew gum, eat foods, or smoke except in places designated for that.

- Keeping health belongings in places far from the areas of operations.

3-3 Means for washing hands:-

- Sufficient, and comfortable hand washing facilities have been provided and when necessary that they use in packing food products in the company that requires good hygienic practices.

- These means are provided with water of a suitable temperature for cleaning of hands with air dryer and these means are kept in a clean and good conditions.

3-4 Means intended for workers

- workers facilities are clean and far from the production area ,It is well equipped and its doors does not open to production halls

- Lockers that are used for keeping workers belongings sealed and clean.

- The Workers ‘dressing room is far from the production area and it is not allowed to eat, drink and smoke in it.

- The dining rooms are equipped with baskets for collecting garbage to prevent pollution.

- The personal protective clothes are separated from the worker’s clothes (uniform) inside the Locker.

- Shoes are placed on the floor under the Locker, not inside, to prevent contamination of the clothes.

- The dressing room-the dining room-the smoking area are separated from the production areas.

Microbiology lab

3-5 Health of workers, injuries and infectious diseases:

- Sick Workers are prevented from working in production areas until they completely cured.

- Visitors or contractors entering the production areas must be examined by the Safety and Health department.

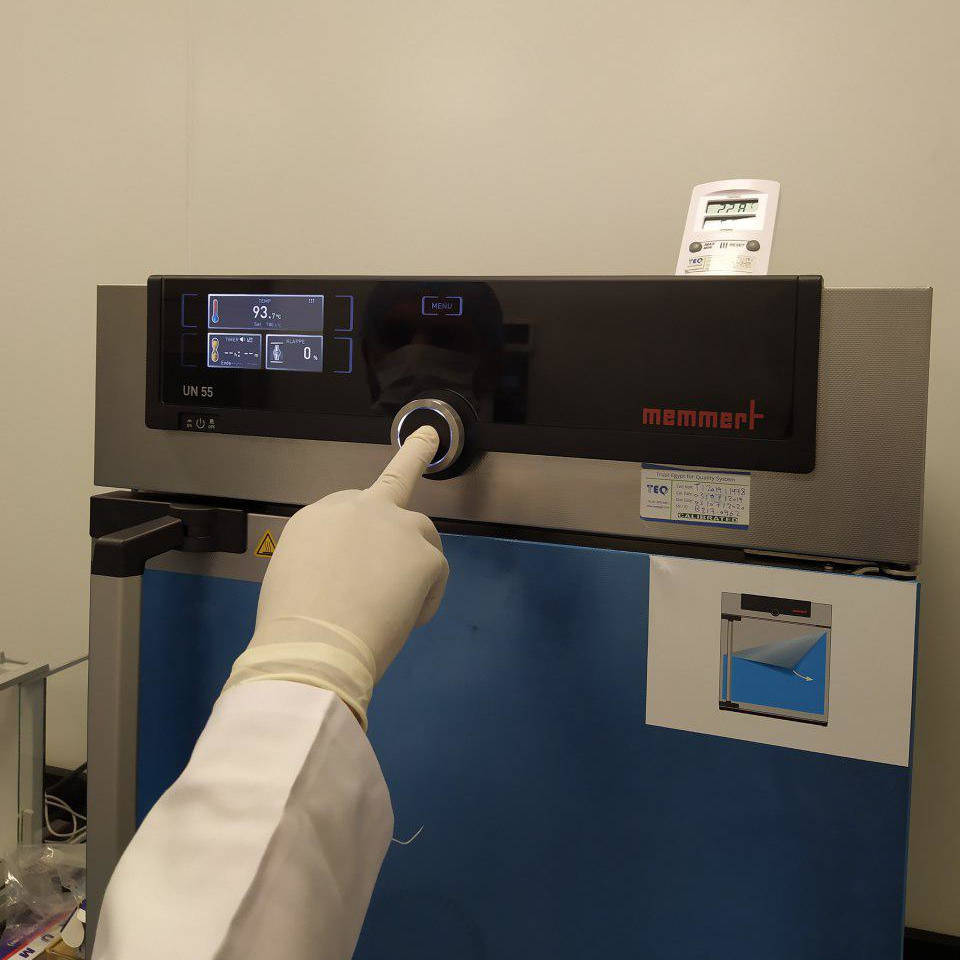

- No one is allowed to be in the production area without wearing the uniform (coat or bodysuit) and for the worker who has direct contact with the product (A head cover that covers the ear – a chin cover for the bearded people – gloves and no jewelry or watches are allowed).

- Before the entering of any person to the production areas he must wash his hands with the disinfectant solution designated for that and this process is repeated if he leaves the departments.

- Quality ,safety ,occupational health supervisors are responsible for supervising the workers to make sure that the worker is not a source of contamination of the product and to ensure the safety of the product.

- Sudden inspection of the general appearance, clothe and other details.

3-6 The outward appearance, the uniforms of the staff, which include the following:

- An uniform or white robe.

- A tight fitting head cover for all hair.

- Clean shoe.

- Gloves that are fit and clean.

- The hair is well groomed and short.

- There are no wounds, blisters, boils, sores, or wounds covered with medical tape.

- Nails are short and clean.

- Not to wear jewelry and watches.

- The worker should not be infected with infectious diseases and in the case of his infection he should inform the administration to exempt him from work.

Other details are done periodically by occupational Health and Safety personnel and in any lack of conformity conditions, the production manager, occupational Health and Safety manager and Quality, and Food Safety manager must be notified and taking sterilization process. The following are inspected in the direct interaction stages with food products.

3-7 warning:-

- Prevent eating or drinking in the workplace or the store or dressing rooms.

- No Smoking inside the factory and stores, but it should be in the designated area.

- Avoid putting hands in the mouth, nose, ears, or touching hair.

- Wash and sterilize hands well with detergent, taking care of the nails and the area between the fingers. Hands are rinsed well with water

- Hands are dried using an air dryer or tissue that should be thrown into covered litter boxes.

- Hands are washed and disinfected in food product packaging areas as following: –

- Before the start of the shift work (production and quality).

- After returning from breaks and after eating and drinking.

- After leaving the restroom

- After leaving the production hall and returning to it.

- Ensure that clothes are clean and washed on time, whether in the company’s laundry or washing at home, with the necessary precautions made by sterilizing them either with chlorine or one of the disinfection materials

- Robes or uniforms, headgear and protective footwear are to be worn when workers enter the production hangar.

3-8 Instructions for treating workers’ wounds:

In the case of injury to one of the workers of the company ,the supervisor should sent him to the medical clinic for treatment as following :

- Cleaning and disinfected of places that contaminated with blood as soon as the workers goes out.

- The clinic doctor disinfects the wound and determines his treatment (inside the factory) or outside (in the hospital).

- In the case that a simple treatment is required, the wound is cleaned and disinfected with an antiseptic and wrapped with a suitable plaster, and the worker is not returned to the place of his work.

- In the case that he needs a hospital, the factory director is informed to take the necessary action.

- Any injured worker must not be returned to his work until he healed

- A medical examination is carried out in health insurance, then medically appropriate workers are assigned to work and a medical card is done for them.

- It is through one of the company’s affiliated hospitals, and workers are sent to do an annual medical examination.

- The results of the hospital are recorded each time from the periodic examination of the workers to follow up their health conditions.

- Ensure that the health cads for workers are valid.

About Emisal

The company was established with the primary environmental objective of improving the salinity concentration of Qarun lake in the appropriate boundaries of marine life because of the environmental, economic and social importance to the surrounding community and Egypt in general, by building an industrial base at the lake site to extract and manufacture a variety of products such as table salt and industrial salts and present their products to the local, Regional, and global markets.

important links

Our social networks